- +90 236 233 20 03

- info@metamold.com

- Customer Portal

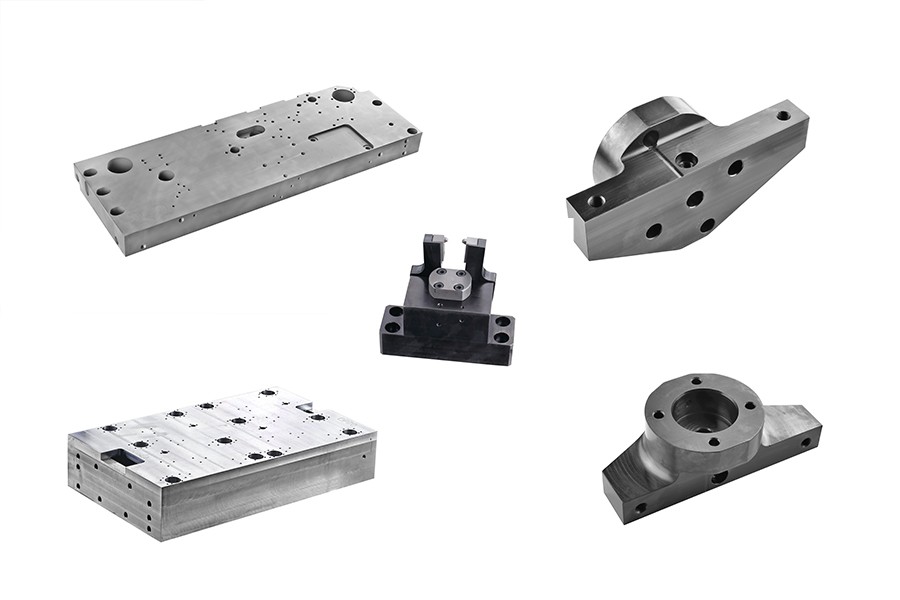

Precision machining of machine parts is a manufacturing discipline that plays a critical role in industrial production processes and requires high precision. The parts used in sectors such as automotive, aerospace, medical, and electronics directly affect the efficiency and reliability of production. Precision machining ensures that even the smallest details are produced accurately with minimal error margins. Precision machining of machine parts refers to the production of complex shapes and low-tolerance parts from materials such as metal, plastic, and ceramics. This process is done using CNC (Computer Numerical Control) machines, lathes, mills, and other precision machining equipment.

Precision machining is a production method that allows materials to be machined with millimetric precision. In this process, high-precision equipment such as CNC machines, milling machines, and lathes are typically used. Precision machining is used in industries such as automotive, aerospace, and medical devices, where narrow tolerances and fine details are required. In these fields, where even the smallest errors are unacceptable, precision machining processes guarantee perfect fit and high performance.

Metamold has the capacity to produce high-demand products in the automotive, aerospace, defense, and medical sectors with its specialized solutions offered to customers. Equipped with CNC machines and advanced technology equipment, Metamold has the ability to machine even parts with the most complex geometries with low tolerances.

Metamold meticulously follows quality control stages in the production process of precision machine parts and continuously makes improvements to meet customer expectations at the highest level. Simulation-supported design processes carry out durability and performance analysis of parts before production.

The precision machining production process is an advanced manufacturing method used in the production of parts requiring high precision and low tolerances. Precision machining is typically performed using digitally controlled equipment such as CNC machines, lathes, mills, and drilling machines. This process allows even the most complex geometries to be produced with perfect accuracy. Precision machining is widely used in many industries, including automotive, aerospace, defense, and medical.

1- Design:

The precision machining production process begins with the design phase. In this phase, the technical drawings of the part are created using CAD (Computer-Aided Design) software. These designs include the geometry, dimensions, and tolerances of the part. A good design is critical for the success of the precision machining process.

2- Prototype and Simulation:

After the design is completed, the prototype creation and simulation phase follows. CAM (Computer-Aided Manufacturing) software simulates the machining processes to be performed on the part. This allows any errors or inconsistencies in the process to be tested before the part is machined, and necessary corrections can be made. Additionally, prototype production is used to test the performance of the part.

3- Material Selection:

The materials to be used in the precision machining process are selected according to the needs of the part to be produced. Metals such as aluminum, steel, titanium, copper, and brass are commonly preferred. Additionally, engineering plastics and ceramics can also be used in precision machining processes. Material selection directly affects the durability, performance, and cost of the part.

4- Machining:

During the machining phase, advanced technology equipment such as CNC machines is used to start machining the part. Various machining methods such as turning, milling, drilling, and grinding are employed to achieve the geometry and surface quality of the part. CNC machines are digitally programmed and process parts with very low error margins. Multi-axis CNC machines enable the production of parts with complex geometries.

5- Quality Control and Testing:

Quality control is extremely important in the precision machining production process. Advanced measurement devices such as coordinate measuring machines (CMM) are used to verify whether the parts meet the desired tolerances and surface smoothness. These devices provide precision at every point by performing three-dimensional scans of the parts. Additionally, material durability, wear resistance, and performance tests are also conducted at this stage.

6- Surface Treatment and Polishing:

At the end of the production process, parts undergo final operations. In this phase, processes such as polishing, grinding, or coating can be applied to enhance surface smoothness. Final processing ensures that the parts are brought to the best state both aesthetically and functionally.

The advantages of precision machining of machine parts create significant differences in production processes: High Precision and Accuracy; Working with tolerances as small as one thousandth of a millimeter ensures perfect fit of parts. Durability; Precision machined parts are long-lasting and high-performing. Efficiency; Using advanced technology machines, large quantities of parts can be produced in a short time with minimal waste. Complex Part Production; High-precision equipment such as CNC machines enable the production of parts with complex geometries.

Quality Control in Precision Machining of Machine Parts

Quality control is an integral part of the precision machining process. Advanced measurement devices are used to check whether each produced part has the correct tolerances. This minimizes the error rate that may arise during the production process.

What is precision machining?

Precision machining of machine parts refers to the production process of parts requiring high precision. In this process, advanced technology equipment such as CNC machines, lathes, and milling machines are used to machine parts with narrow tolerances. It is commonly used in industries such as automotive, aerospace, and medical.

What are Precision Machine Parts?

Precision machine parts are defined as parts that require tolerances at the extremely low level and precision at one thousandth of a millimeter. These parts are produced using advanced manufacturing tools such as CNC machines and laser cutting technologies. Whether small parts at the millimeter level or larger machine components, the production of precision machine parts requires detailed planning and specialized manufacturing techniques.

What materials are used for precision machining?

Precision machining can be applied to a wide range of materials, including metals (aluminum, steel, titanium), plastics (ABS, nylon, acrylic), ceramics, and composite materials. Material selection depends on the sector where the part will be used and the desired features.

Why are CNC machines used for precision machining?

CNC machines allow for the machining of complex and precise parts with high accuracy due to their computer control. CNC machines produce with repeatability, precision, and minimum error margins, maintaining quality even in large production volumes.

What are the advantages of precision machining?

It provides high precision and accuracy.

It can produce parts of the same quality in large-scale productions.

It reduces waste rates and provides cost savings.

It produces durable and long-lasting parts.

What are the disadvantages of precision machining?

It can be expensive, especially for complex and low-tolerance parts.

The machining time can be long as it requires detailed and fine craftsmanship.

Some hard and durable materials may be difficult to machine precisely.

What types of surface treatments can be done with precision machining?

In precision machining processes, surface finishing, polishing, grinding, and similar processes can be performed. This is important for the surface smoothness and aesthetic appearance of the parts in the final stage.

In which industries is precision machining used?

It is widely used in sectors such as automotive, aerospace, medical, electronics, and defense industry. Precision machining is critically important for reliability and performance in these sectors.