- +90 236 233 20 03

- info@metamold.com

- Customer Portal

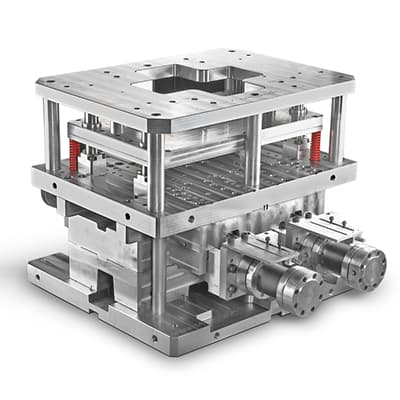

At Metamold, we lead the industry with our expertise and innovative approaches in aluminum casting molds. With our high-precision and durable mold solutions, we optimize your production processes, reducing costs and increasing efficiency. Our experienced team and state-of-the-art equipment guarantee timely and complete delivery of your projects. If you're looking for a reliable partner in aluminum casting molds, Metamold is the right address for you.

Aluminum casting molds are tools that allow molten aluminum to be poured into a mold to achieve the desired shape. These molds are used in sectors such as automotive, aerospace, electronics, and construction for producing detailed and complex parts. They are manufactured with high precision and made from materials resistant to high temperatures. The molds generally have a long lifespan, provide high efficiency in production, and enhance product quality standards with special cooling mechanisms. The lightness, durability, corrosion resistance, and workability of aluminum make these casting molds ideal for industries.

The prices of aluminum casting molds vary depending on many factors such as the complexity of the mold, size, production quantity, materials used, design and engineering costs, surface treatments, and production location. Complex and large molds are more expensive, while simple and small molds are more economical.

To determine an accurate cost, it is best to obtain a special quote based on project requirements and production volume.

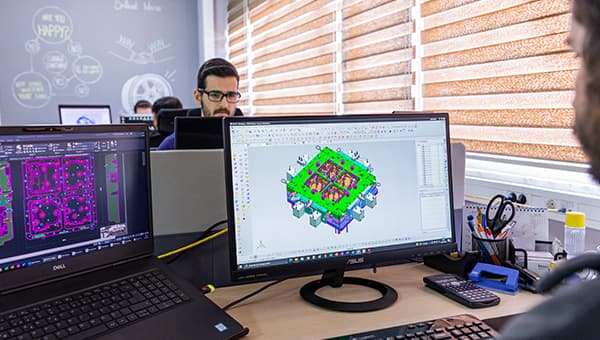

Metamold, a manufacturer of aluminum casting molds, serves sectors such as automotive, aerospace, electronics, and construction, producing molds that meet high-quality standards. Metamold is noted for its use of advanced technology, expert teams, certification, and R&D investments.

General Features of Metamold

The design of aluminum casting molds is critical for the quality of the produced part and the efficiency of the production process.

Important factors to consider in design

The manufacturing of aluminum casting molds is a process requiring high quality and precision, executed with advanced technology and expertise. The molds enable molten aluminum to form the desired parts and should be durable and reusable.

Production Stages:

Technologies Used:

Superiorities Compared to Other Molds:

Automotive Industry

Used in the production of engine blocks, cylinder heads, pistons, gearboxes, suspension parts, and chassis components.

Aerospace Industry

Preferred for producing critical parts such as aircraft engine components, landing gears, structural components, and satellite parts.

Electrical and Electronics Sector

Used in the production of electric motors, cooling elements, electronic device housings, and connectors.

Construction and Infrastructure Sector

Used in the production of structural elements, railings, stair treads, and door-window frames.

Defense Industry

Used in applications requiring high durability, such as armored vehicle parts, weapon components, and radar equipment.

Energy and Renewable Energy Sector

Preferred in the production of wind turbine components, solar panel frames, and generator parts.

Consumer Electronics

Provides aesthetics and durability in products such as smartphone bodies, laptop casings, and television frames.

Medical and Healthcare Sector

Used in the production of medical device housings, prosthetic parts, and surgical tool components.

Machinery and Equipment Manufacturing

Involves the production of pump bodies, compressor components, and industrial robot parts.

Home and Office Furniture

Used in chair and table legs, decorative accessories, and lighting equipment.

Maintenance Processes:

Repair Processes:

What is an aluminum casting mold?

An aluminum casting mold is a mold that allows molten aluminum to be poured into it to shape it. These molds are usually made of steel and enable the molten metal to solidify according to the designated shape within the mold during the casting process.

What are the application areas of aluminum casting molds?

Aluminum casting molds are used in many sectors, including automotive, aerospace, electronics, construction, defense, energy, consumer electronics, and medical. They are commonly preferred in places where lightweight, durable, and precise parts are produced.

How durable are aluminum casting molds?

Aluminum casting molds are made of durable steel or hot work steels, allowing them to withstand thousands of casting operations. The lifespan of the mold can vary based on the materials used, the production process, and maintenance. Regular maintenance and proper use can extend the mold's life.

How precise are aluminum casting molds?

Aluminum casting molds are ideal for producing complex geometries, fine details, and precise parts. These molds are used in high-precision production and are generally preferred in the automotive and electronics industries.

What is the cost of aluminum casting molds?

The cost of aluminum casting molds varies based on the size, complexity, and materials used in production. Initially, the cost of producing a mold can be high, but in mass production, the mold cost per unit significantly decreases. Generally, simple molds start from a few thousand dollars, while complex and large molds can reach tens of thousands of dollars.

What is the difference between aluminum casting molds and sand casting molds?

Aluminum casting molds are made from reusable metal molds, while sand casting molds consist of single-use sand molds. Aluminum casting molds offer higher precision and surface quality, whereas sand casting molds are more suitable for low production volumes and large parts. Since sand casting molds must be recreated for each casting operation, they can be costly in mass production.

What materials can be cast with aluminum casting molds?

Aluminum casting molds are generally used for casting lightweight metals such as aluminum, magnesium, and zinc. These molds can withstand high temperatures and pressures, allowing casting of materials beyond lightweight metals.

How should aluminum casting molds be maintained?

Aluminum casting molds should be regularly cleaned, their surfaces inspected, lubricated, and cooling channels kept clear. Additionally, the functionality of the mold's mechanical parts should be checked and worn parts repaired. If periodic maintenance is not performed, the molds' lifespan may shorten and casting quality may decline.

What factors should be considered in mold design?

Factors to consider in mold design include the geometry of the part, thermal expansion during casting, shrinkage allowance, cooling process, ventilation holes, and the flow of metal into the mold. A well-designed mold speeds up the production process, improves quality, and minimizes casting errors.

What sizes of parts can be produced with aluminum casting molds?

Aluminum casting molds are generally used for producing small and medium-sized parts. However, they can also be used for larger parts, but mold costs and complexity may increase. Sand casting may be a more suitable method for very large parts.

What casting methods are aluminum casting molds used in?

Aluminum casting molds are commonly used in high-pressure casting (HPDC), low-pressure casting (LPDC), die casting, and injection molding methods. Each method varies based on factors such as production volume, part precision, and cost.

What are the biggest advantages of aluminum casting molds?

High precision and capacity to produce detailed parts. Suitability for mass production. Smooth surface quality. Longevity and reusability. Rapid production processes.

What surface treatments can be applied to aluminum casting molds?

Various surface treatments can be applied to aluminum casting molds to achieve smooth and durable surfaces after production. These include polishing, grinding, nitriding, PVD (Physical Vapor Deposition), and other coating processes. These treatments increase wear resistance, extending the mold's lifespan.

What is the delivery time for aluminum casting molds?

The delivery time for aluminum casting molds varies based on the complexity, size, and production process of the mold. It can typically range from a few weeks to several months. In complex and large projects, the time may be extended.

What are the environmental impacts of aluminum casting molds?

Aluminum casting molds are environmentally friendly options as they work with recyclable materials like aluminum. Additionally, since the molds are suitable for long-term use, they reduce waste generation. However, considering the energy and resources used in the production of molds, energy-efficient methods should be preferred for a sustainable production process.