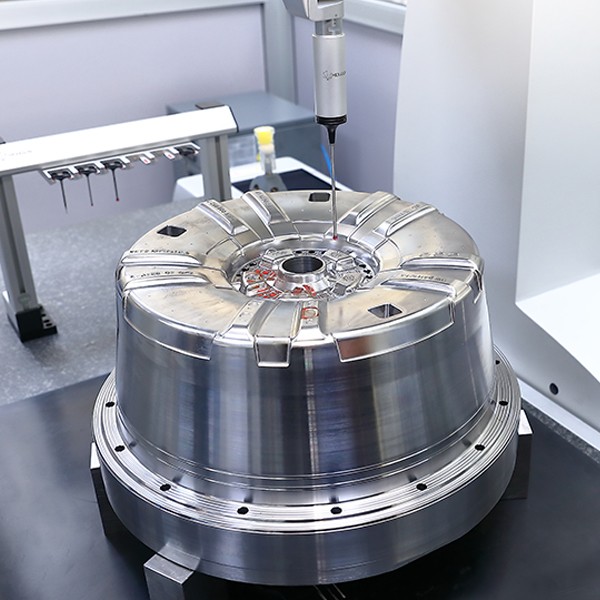

At Metamold, our expertise in reverse engineering enables us to deliver high-quality products tailored to our customers' needs. Whether it is a simple component or a complex product, we strive to provide the most effective solution, guided by a meticulous process from design to production.

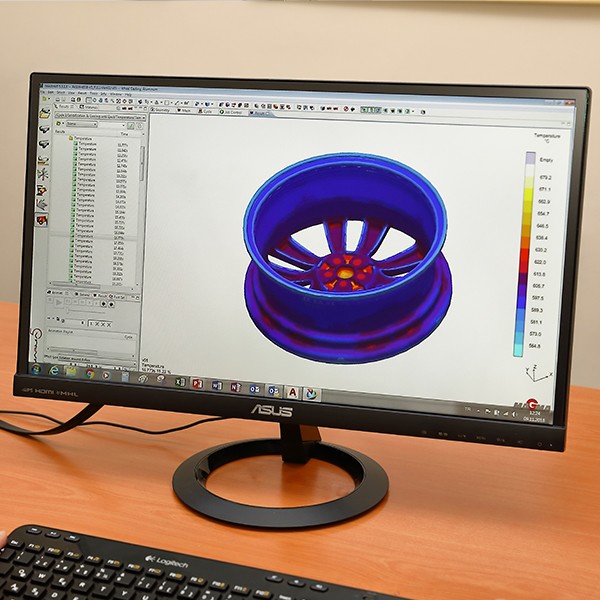

When we comprehensively analyze the original product, our team creates detailed CAD (Computer-Aided Design) data, taking into account product features (modifications, transitions' rigidity and softness, as well as edges, corners, surfaces, etc.). Our reverse engineering team then implements the desired changes in the CAD model based on the requests and requirements provided. Once the design is prepared in the CAD model, the product undergoes testing and quality control before moving to the production phase. Using the latest manufacturing techniques, we transform the design developed through reverse engineering methods into a product that meets standards of quality and innovation.