- +90 236 233 20 03

- info@metamold.com

- Customer Portal

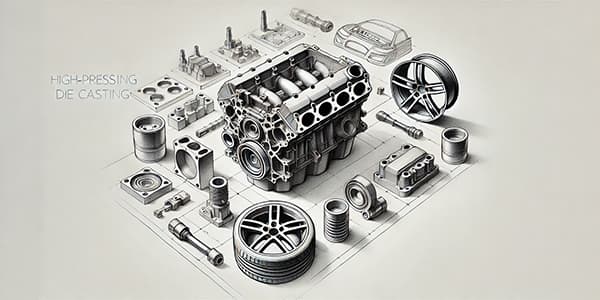

At Metamold, we provide solutions that meet the industry's expectations by prioritizing quality and precision in high pressure die casting (HPDC) molds. HPDC molds are produced using advanced technology, the experience of our expert team, and comprehensive quality control processes. While offering our customers fast, durable, and efficient production capabilities, we provide a competitive advantage with long-lasting, high-performance molds. Thanks to our advanced engineering solutions and innovative design approaches, we offer flexible production solutions tailored to each project.

HPDC (High Pressure Die Casting) Mold is a production method in which metal alloys are melted and injected into molds under high pressure. This method allows for the fast and high-quality processing of lightweight metal alloys such as aluminum and magnesium. HPDC molds are an essential part of modern industry due to their efficiency and quality advantages.

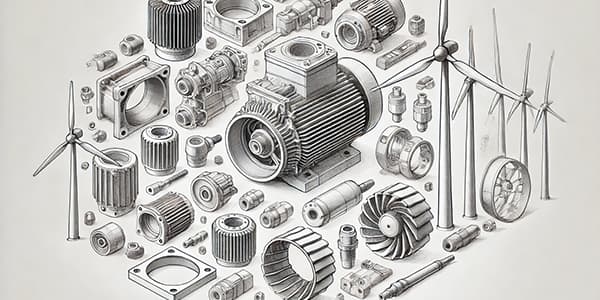

HPDC (High Pressure Die Casting) molds play a crucial role in providing high-quality and fast part production in various industries. By enabling the production of durable and lightweight parts, HPDC molds hold an important place in the development of modern industry.

Automotive Industry

Aerospace Industry

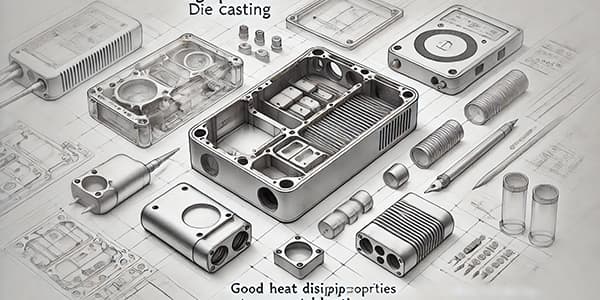

Electronics Industry

Other Industries

HPDC molds have become an indispensable part of modern industry due to their high precision, fast production, and quality advantages. These advantages are the main reasons why HPDC technology is preferred in many industries such as automotive, aerospace, electronics, and home appliances.

High Precision

Detailed Design Application: Allows the rapid and detailed production of complex-shaped parts under high pressure. Low Tolerances: Production with low tolerances reduces the possibility of errors in assembly and increases compatibility. High Surface Quality: Obtaining smooth surfaces reduces the need for additional processing, thus lowering costs.

Production Speed

Fast Casting Process: The metal is quickly injected into the mold, making the production process very fast. Short Cycle Times: Casting cycles are completed in a short time, increasing machine efficiency. High Automation: Processes are often automated, reducing labor costs.

Quality Advantages

Durability and Strength: High pressure compresses the atomic structure of the metal, producing more durable parts. Fewer Defective Parts: Reduces error rates in the production process, minimizing waste and the need for rework. Material Efficiency: Minimizes material waste, providing cost-effective production.

The design and production process of HPDC (High Pressure Die Casting) molds plays a critical role in producing high-quality and durable parts. This process requires careful planning and engineering. The design and production process of HPDC molds must be carefully managed to ensure high precision and quality. Applying the correct design principles and production stages ensures the production of durable and quality parts. Therefore, HPDC technology stands out as an essential element of modern industry.

Design Principles:

Production Process:

Regular maintenance and repair of HPDC molds are crucial for maintaining production quality and extending the life of the molds. Cleaning, lubrication, regular inspections, and repair methods increase the efficiency of the molds, thus enhancing the productivity of production processes. Implementing effective maintenance and repair processes forms the foundation of a successful HPDC production process.

The prices of HPDC (High Pressure Die Casting) molds vary depending on various cost factors and production conditions. HPDC mold prices are influenced by factors such as design, material, production process, size, and complexity. It should be noted that high-quality and durable molds provide cost-effectiveness in the long run. When purchasing molds, attention should be paid not only to initial costs but also to the value and efficiency they offer throughout their lifespan.

Cost factors play a significant role in mold production, and different elements directly affect costs. First, mold design and engineering can increase costs, as the complexity of the design and special requirements require more time and expertise. Mold materials are also a major factor. When materials like hardened steel, aluminum, or special alloys are used, the durability of these materials can balance costs in the long term, but initial costs may be high.

The production process also affects costs. Especially machining times and the quality of the machines used are key determinants of total cost. CNC machines increase quality but also raise costs. Additionally, mold size and complexity are other factors affecting costs. Larger and more detailed molds require more materials and labor, which increases costs.

Finally, coating and processing stages also affect costs. Coatings applied to the mold surface provide long-term advantages by extending mold life, but they can increase initial costs. Maintenance and repair of molds, when done regularly, extend the mold's service life and reduce overall costs, but repair processes can also add additional costs.

Metamold offers high-quality service by using the latest technologies and engineering solutions in the production of HPDC molds. High technology, expert teams, and quality materials are at the forefront of their production processes. Customizable solutions, certified production, and long-lasting, durable designs are provided to customers. Metamold is recognized as a leader in HPDC mold production in both Turkey and the international market. It serves to provide tailored solutions for customer projects.

Certification and quality control processes in the production of HPDC (High Pressure Die Casting) molds play a critical role in ensuring the quality and reliability of the product. These processes have significant impacts both during production and on the performance of the final product. Certification and quality control processes of HPDC molds guarantee high-quality standards. These processes enhance product reliability and competitiveness while improving mold quality. Applying these processes effectively in the production of HPDC molds is the key to a successful production process.

Certification Processes

Quality Control Processes

What is an HPDC Mold?

HPDC (High Pressure Die Casting) mold is a mold produced by injecting metal alloys into molds under high pressure. It allows for the fast and high-quality production of parts with complex shapes.

What Materials Are HPDC Molds Made From?

They are usually made of hardened steel, aluminum alloys, and sometimes copper alloys. These materials are selected for their resistance to high temperatures and pressure.

What Are the Advantages of HPDC Molds?

They offer high precision, fast production times, high surface quality, low error rates, and durability.

How Are HPDC Molds Designed?

They are designed using CAD software, taking into account factors such as mold geometry, fluidity, cooling systems, and mold material.

What Is the HPDC Mold Production Process?

It consists of design, material selection, machining, assembly, casting, cooling, and quality control stages.

How Are HPDC Molds Maintained and Repaired?

Maintenance includes regular cleaning, lubrication, checking the cooling system, and inspection. Repair methods include reworking worn surfaces, welding repairs, and renewing coatings.

What Are the Prices of HPDC Molds?

Prices vary depending on the size and complexity of the mold. Basic molds typically range from 5,000 to 15,000 USD, while complex molds can go up to 50,000 USD.

In Which Industries Are HPDC Molds Used?

They are used in the automotive, aerospace, electronics, home appliances, and energy sectors, preferred for the production of lightweight and durable parts.

How Is Quality Control Done for HPDC Molds?

It involves stages such as incoming inspection, process control, final product inspection, and performance testing.

Why Is Certification Important for HPDC Molds?

Certification ensures that products meet certain standards; this is important in terms of quality, reliability, and environmental management, increasing competitiveness in the market.