- +90 236 233 20 03

- info@metamold.com

- Customer Portal

As one of the leading companies in the industry, Metamold combines high technology and expert engineering in low-pressure casting molds. To ensure maximum efficiency and quality in production, our molds are designed with the best materials and go through comprehensive testing processes, providing long-lasting and durable solutions. Our continuously evolving processes, backed by R&D investments, ensure that we offer the most suitable solutions to customer demands while guaranteeing quality and reliability. Metamold’s low-pressure casting molds make a difference in production, delivering superior performance even in projects requiring high precision.

A Low Pressure Die Casting (LPDC) mold is a metal casting method in which molten metal is injected into the mold under low pressure. It is particularly used for casting lightweight metals such as aluminum. This method offers advantages such as high-quality casting, low porosity, high material efficiency, and suitability for automation. It is commonly preferred in the automotive industry, especially for the production of durable products such as wheels and engine components.

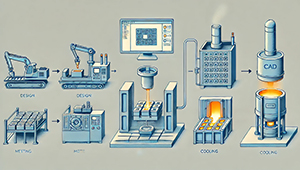

Mold Design: 3D modeling is done using CAD software, appropriate mold material is selected, and casting process simulations are carried out.

Mold Design: 3D modeling is done using CAD software, appropriate mold material is selected, and casting process simulations are carried out. Mold Production: The mold is machined with CNC machines, and surface treatments are applied.

Mold Production: The mold is machined with CNC machines, and surface treatments are applied. Casting Preparation: The metal is melted, and the mold assembly and heating are completed.

Casting Preparation: The metal is melted, and the mold assembly and heating are completed. Casting Process: The molten metal is filled into the mold by applying low pressure and then cooled.

Casting Process: The molten metal is filled into the mold by applying low pressure and then cooled. Removal of Cast Part: The mold is opened, the part is removed, and cleaning is performed.

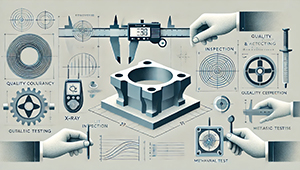

Removal of Cast Part: The mold is opened, the part is removed, and cleaning is performed. Control and Tests: The part undergoes quality control and tests.

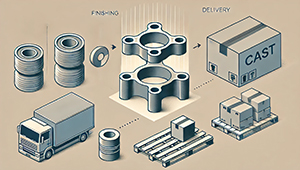

Control and Tests: The part undergoes quality control and tests. Final Processing and Delivery: If necessary, coating is applied, and the parts are prepared for shipment.

Final Processing and Delivery: If necessary, coating is applied, and the parts are prepared for shipment.The prices of Low Pressure Die Casting Molds vary depending on factors such as the materials used, the complexity of the mold design, its size, the production technology, and the quantity. High-quality steel and alloys can increase costs. Complex and large designs are more expensive, while mass production can reduce the cost per mold. Additional features (cooling systems, coatings) and quality control processes also affect the price. Generally, prices range from 10,000 USD to 100,000 USD, with customized and large molds on the higher end of the range.

Mold steels, especially hot work steels like H13 and AISI P20, are commonly preferred in low-pressure die casting molds due to their resistance to high temperatures and wear. Among alloy steels, nickel-chromium and cobalt-based alloys stand out, increasing the thermal resistance and wear resistance of molds. Regarding casting metals, molds suitable for aluminum, magnesium, and copper alloys are preferred, ensuring molds can withstand the casting process of these metals. Graphite, besides its high-temperature resistance, provides good lubrication, helping ensure a smooth casting process. Ceramic materials, particularly ceramic coatings and zirconia, extend the life of molds and offer thermal shock resistance. Coatings and surface treatments such as nitriding and PVD coatings enhance wear resistance, allowing for longer mold life. Heat treatment methods like vacuum hardening are applied to increase the durability and longevity of molds.

What is Low Pressure Die Casting?

It is a casting method in which molten metal is injected into the mold at low pressure, typically used for casting lightweight metals such as aluminum and magnesium.

What Materials are Used in Low Pressure Die Casting Molds?

Durable materials like hot work steel (H13, H11), graphite, ceramic coatings, and nickel-chromium alloys are used.

What are the Advantages of Low Pressure Die Casting Molds?

High dimensional accuracy, less porosity, material efficiency, the ability to produce complex parts, and suitability for mass production.

Where are Low Pressure Die Casting Molds Used?

They are widely used in the automotive, aerospace, electronics, household appliances, defense, and construction industries.

How is the Maintenance of Low Pressure Die Casting Molds Done?

Molds should be regularly cleaned, worn parts repaired, and coatings renewed. Cooling channels and thermal shock control are also important.

How Can Mold Life be Extended?

Regular maintenance, proper temperature and pressure use, protection from thermal shocks, and resting the molds are necessary.

Which Metals Can Be Cast Using Low Pressure Die Casting?

Lightweight metals such as aluminum, magnesium, and copper alloys can be cast.

What are the Differences Between Low Pressure Die Casting and High Pressure Die Casting?

Low pressure die casting results in less porosity and finer details, while high pressure die casting offers faster production.

Why is the Cooling System Important in Low Pressure Die Casting?

It balances temperature, prevents thermal shocks and internal stresses, improves casting quality, and extends the life of the mold.

What is a Runner System in Low Pressure Die Casting?

It is a network of channels that directs molten metal into the mold, ensuring proper casting.

How is a Low Pressure Die Casting Mold Designed?

It is designed with CAD software, and the metal flow and cooling are optimized through simulations.

How are the Prices of Low Pressure Die Casting Molds Determined?

The price ranges between 10,000 USD and 100,000 USD depending on the material, size, and design complexity of the mold.