- +90 236 233 20 03

- info@metamold.com

- Customer Portal

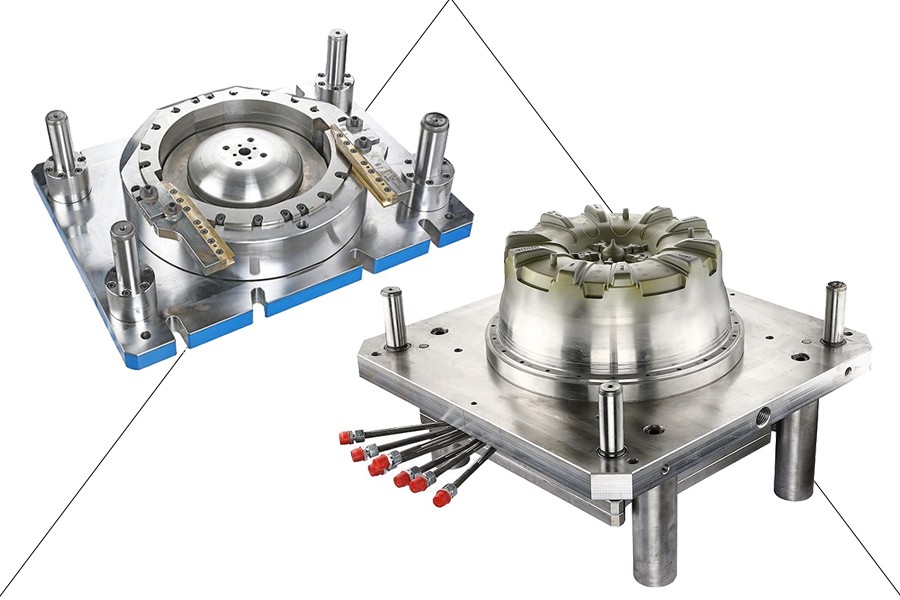

At Metamold, we specialize in mold solutions used in wheel production. Wheel molds play a critical role in the production of parts that require high precision and durability in the automotive industry. In our modern production facilities, we design and manufacture custom-made wheel molds using the latest technology according to customer needs.

With the selection of high-quality materials, detailed engineering designs, and production processes that ensure long-lasting performance, we are a reliable partner in wheel mold manufacturing. We provide tailored solutions to our customers, ensuring they achieve the best production performance. If you want to choose the most efficient wheel molds for your projects, you can contact our expert team right away.

Wheel molds are used for the production of wheels, primarily in the automotive industry and various other sectors. These molds define the design, size, and geometry of the wheels and are typically used in casting or injection methods.

Uses:

Importance:

The wheel mold production process requires high precision and involves both engineering and manufacturing stages. Quality and durable wheels can only be produced through accurate mold design and manufacturing. This process includes several steps, each requiring detailed planning and expertise.

Needs Analysis and Project Planning: The first step in the wheel mold production process is determining customer needs and product specifications. In this phase, the size and type of the wheel are determined according to the vehicle type, material selection (usually aluminum, steel, or alloy) is made, and the production quantity along with mass production requirements are planned to ensure cost-efficiency.

Wheel Mold Design: In the wheel mold design phase, CAD software is used to create a 3D model of the wheel. The geometry, surface roughness, hole structure, and aesthetic elements of the wheel are designed. Simulations are run to test production accuracy and material flow, detecting potential issues beforehand. Additionally, thickness, weight distribution, and tolerance settings are adjusted for wheel strength and performance.

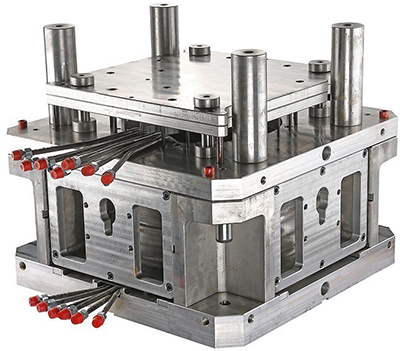

Mold Manufacturing: Once the design is approved, the molds are precisely machined using CNC machines to achieve the desired geometry and surface quality. Heat treatment is applied to increase the durability of the mold, and polishing and coating processes are carried out to enhance surface quality. During the assembly stage, mold parts are combined, and the mold's performance is tested with initial trial productions.

Production Process: After the mold is produced, the wheel is manufactured using casting or injection methods. In casting, molten metal is poured into the mold, while in injection, the molten material is injected under high pressure. After production, the wheels go through detailed quality control processes such as dimensional inspection, surface quality checks, and strength tests. These steps ensure that the wheels are safe and durable.

The prices of wheel molds are determined by various factors. The cost of wheel molds depends on labor, materials used in the production process, design complexity, and production capacity.

Metamold is one of the leading companies in Turkey specializing in wheel mold production. Known for its commitment to high quality and customer satisfaction, Metamold stands out with its wide product range and use of advanced technology. The company has specialized in producing highly precise wheel molds, meeting the demands of the automotive industry with innovative solutions.

Metamold's expertise includes aluminum injection molds, low-pressure die casting molds, and wheel molds. With its advanced engineering knowledge and modern production technologies, Metamold is a leader in the industry, providing customers with high-quality and durable products.

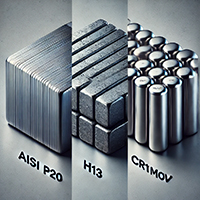

The materials used in the production of wheel molds directly affect their durability, performance, and costs. Material selection depends on the type of wheel, production method, and technologies used. Choosing the best materials is critical for producing long-lasting and high-quality molds.

Regular Cleaning

Regular cleaning is critical to prolong the lifespan of wheel molds. During production, metal residues, oil, and dust accumulate on the molds and should be cleaned, otherwise, it can cause mold wear and decrease production quality. During cleaning, metal particles, oil, and dirt should be removed from the surface using special cleaners, avoiding abrasive chemicals.

Surface Protection and Coating

The mold surface may wear due to high temperatures and pressure during production. Therefore, coating and polishing processes can be applied to protect the surface. Coating methods (chrome, nitride, titanium) reduce friction and harden the surface, while polishing ensures a smooth surface, increasing mold lifespan and production quality.

Heat Treatment and Surface Hardening

Heat treatment increases the durability of wheel molds, making them resistant to wear. This process, especially applied to materials like H13 steel, increases mold hardness and longevity. Additionally, surface hardening processes make molds more resistant to wear and deformation.

Regular Inspection and Control

Regular inspection and control are necessary to ensure the efficient use of wheel molds. Dimensional control compares the original dimensions of the mold with the post-production dimensions, examining deviations. Surface inspections detect cracks, deformations, or wear, preventing production errors and allowing for timely repairs.

Repair and Revision

Repair and revision are essential for maintaining mold production efficiency. Crack repairs should be addressed early; otherwise, cracks may grow, rendering the mold unusable. Wear can be addressed through polishing or refurbishment. Revisions are made when design changes or the application of new technologies are needed, improving mold performance.

Lubrication and Reducing Friction

Lubrication and reducing friction are important to slow down mold wear. The correct choice of lubricant should be made with non-damaging, high-temperature-resistant lubricants. Regular lubrication during production reduces friction before and after each cycle, prolonging mold lifespan.

Storing Molds

Molds should be properly stored when not in use to prevent oxidation and corrosion. Protection from moisture can be achieved by storing molds in dry, cool environments. Protective coatings and sprays can be used to preserve the mold surface, reducing the risk of corrosion.

Training to Prolong Mold Life

Proper training of operators on mold usage and maintenance is important. Improper use can lead to rapid mold deterioration. Operators should receive training on the correct use, lubrication, and maintenance of molds to extend their lifespan.

What is a wheel mold?

A wheel mold is a mold used in wheel production. It is usually made from durable materials such as aluminum or steel and ensures the wheel is produced in the desired form and structure. Wheel molds are used in manufacturing methods such as casting and injection.

What materials are wheel molds made of?

Wheel molds are typically made of high-durability materials such as steel or aluminum. These materials are resistant to high temperatures and pressures and ensure the longevity of the molds.

How are wheel molds produced?

Wheel mold production begins with the design phase. A mold model is created using Computer-Aided Design (CAD). The mold is then manufactured using suitable materials. The production process includes various steps such as casting, milling, and CNC machining.

How much do wheel molds cost?

The price of wheel molds varies depending on the material used, the size of the mold, the complexity of the design, and the production method. Generally, wheel molds can be found in a wide range of prices, from small-scale to large industrial productions.

How long does it take to manufacture a wheel mold?

The manufacturing time for a wheel mold depends on the complexity of the mold, production capacity, and design stages, typically taking several weeks. Complex and large molds may take longer, while simpler molds can be completed in a shorter time.

What are the differences between aluminum wheel molds and steel wheel molds?

Aluminum wheel molds are lighter and easier to process, while steel wheel molds are more durable and resistant to high pressure. Steel molds are generally longer-lasting, but aluminum molds may be lighter and more economical.

How is wheel mold maintenance and repair done?

Regular maintenance of wheel molds is important to extend their lifespan and ensure production efficiency. After use, the molds should be cleaned, surface wear should be checked, and repairs should be made if necessary. Repair methods such as CNC machining or welding can be used for mold maintenance.

In which industries are wheel molds used?

Wheel molds are used in various sectors, especially in the automotive industry, agricultural machinery, and industrial vehicles. Wheel production is carried out with high precision through these molds.

How are wheel molds designed?

Wheel molds are designed using CAD software in a digital environment. The design considers the dimensions, geometry, and durability criteria of the wheel. Afterward, the mold is manufactured according to this design.

Where can I obtain wheel molds?

Wheel molds can be obtained from mold manufacturers or foundries that specialize in custom production. Additionally, automotive spare parts manufacturers and suppliers may also provide these molds.