- +90 236 233 20 03

- info@metamold.com

- Customer Portal

A casting mold is a mold made of metal or special alloys that is used to ensure the solidification of liquid metal into a specific shape and size. These molds help the metal take the desired form during the casting process and play a critical role in many industries.

A casting mold is a tool that allows liquid metal to be poured into it and to transform into a specific product or part shape as it cools and solidifies. It generally consists of a mold body and a mold core; the body forms the outer structure while the core creates the inner structure and is used to create internal cavities. Casting molds can be made from various materials such as aluminum, steel, and silicone.

This is the oldest and most common type of mold that uses sand, usually prepared with a mixture of silica sand, bentonite, and water.

Advantages:

Areas of Use:

These are produced from durable materials such as metal or alloy. Liquid metal is poured into the mold and cooled.

Advantages:

Areas of Use:

Liquid metal is supplied to the mold under low pressure, typically suitable for aluminum.

Advantages:

Areas of Use:

Liquid metal is injected into the mold under high pressure.

Advantages:

Areas of Use:

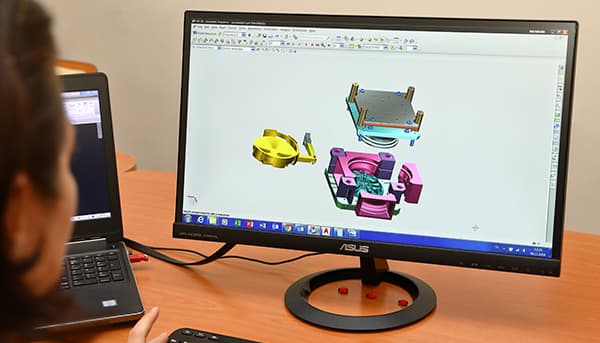

Part Design: The properties, dimensions, and geometry of the part to be produced are determined. Mold Structure: The material and type of the mold (sand, die, LPDC, HPDC) are selected; factors such as moldability, cooling channels, and air vents are also taken into account. Analysis of the Casting Process: Simulations of the casting process are conducted to prevent potential adverse effects. Use of CAD Software: Mold design is carried out digitally using computer-aided design (CAD) software.

Mold Production: After the design is approved, mold parts are produced with the necessary materials (sand casting or metal casting process). Mold Assembly: The produced parts are assembled according to the specified design. Finishing Operations: After assembly, surface treatments of the mold (sanding, polishing) are carried out. Testing and Control: The mold is subjected to various tests; these tests are conducted to check whether the mold operates correctly. Mass Production: Once the tests are successful, the desired parts are produced by pouring liquid metal using the mold.

Materials for Sand Casting Molds

Materials for Die Casting Molds

Materials for Low-Pressure Die Casting (LPDC)

Materials for High-Pressure Die Casting (HPDC)

The advantages of using casting molds are crucial for optimizing production processes, reducing costs, and achieving high-quality products. These benefits clearly demonstrate why casting molds are so widely used in industrial production.

High-Quality Part Production

Detailed Design Possibilities: Allows for the production of complex geometric shapes and detailed designs, ensuring high aesthetic and functional quality of the parts.

Low Error Rate: The controllable casting process reduces the error rate and makes the dimensions and shapes of the produced parts more consistent.

Surface Quality: Helps achieve smoother surfaces, which is important for products with aesthetic requirements.

Reducing Production Costs

Advantages of Mass Production: Casting molds are suitable for producing multiple parts, which increases production efficiency and reduces costs.

Less Waste: Minimizes material waste; the amount of metal used is calculated appropriately based on the shape of the parts to be produced, thus minimizing waste.

Fast Production Process: Increases competitiveness by responding more quickly to market demands with fast production times.

Flexible and Durable Structures

Different Material Options: Being able to be produced from various metals and alloys provides flexibility suitable for industrial needs.

High Durability: With their long-lasting and durable structures, they can be reused multiple times.

Resistance to Environmental Conditions: Designed to withstand high temperatures and pressure, maintaining performance even in harsh conditions.

The prices of casting molds vary based on the type of mold, material, design complexity, and production quantity.

Casting molds play a critical role in the production of metal and alloy parts. In this context, high-quality casting mold manufacturers are essential for achieving success in industrial production processes.

Quality and Reliability: The quality of casting molds directly affects the durability and performance of the final products. Metamold produces casting molds using only high-quality materials and modern production techniques. This ensures reliable and long-lasting molds that meet our customers' needs.

Advanced Technology: Metamold continually improves its production processes by keeping up with the latest technological developments. By using advanced technologies such as CAD/CAM software and 3D printers, we make mold design and production more efficient.

Customized Solutions: Each industry has different needs. Metamold provides custom casting mold solutions, designing and producing molds suitable for each project. This aims to enhance the competitive advantage in the industry.

Expert Team: Metamold's team of experienced engineers and technicians provides professional support at every stage of projects. By offering expertise throughout the entire process from design to production, we aim for high customer satisfaction.

Environmentally Friendly Production: Metamold adopts an environmentally conscious production approach. We save energy and manage waste effectively while producing our casting molds. This contributes to a sustainable future.

Among casting mold manufacturers, Metamold stands out with its quality, reliability, and customized solutions. With our customer-oriented approach and innovative production methods, we are here to meet your casting mold needs.

Casting Molds:

Plastic Molds:

Performance:

Durability:

Simulation technologies in the design and production processes of casting molds play a critical role in reducing error rates, increasing efficiency, and optimizing the production process. These technologies can be utilized starting from the mold design phase. The simulation technologies used in casting molds allow for the more effective and efficient management of production processes. Casting simulation provides error detection and optimization during the design phase, while software (especially Magmasoft) helps to conduct this process more quickly and accurately. The use of such technologies is crucial for both improving production quality and reducing costs.

Casting simulation is a technology used to model the casting process of liquid metal and its behavior within the mold in a digital environment. Through this process:

Magmasoft is one of the most popular and effective software for casting simulation.

Other simulation tools include:

What is a Casting Mold?

A casting mold is a mold that allows liquid metal to be poured and take the desired shape. These molds are used in the production of metal parts and are typically made from materials like sand, aluminum, steel, or bronze. The mold contains a cavity in which the metal takes shape, and this cavity is formed according to the design of the part.

What Materials Are Casting Molds Made From?

Casting molds are made from different materials depending on the casting technique used and the properties of the metal to be cast. Sand molds are made by mixing sand with binding agents, while die casting uses durable materials like steel or cast iron. High-temperature resistant ceramic molds can also be preferred.

What is a Sand Casting Mold?

A sand casting mold is a disposable mold made from silica sand and binding agents, used in metal casting processes. Sand casting is suitable for producing large and complex parts and is low-cost. However, a new mold must be prepared for each casting process.

What is a Die Casting Mold?

A die casting mold is a mold that can be continuously used, typically made from materials such as steel or cast iron. These molds produce parts with high surface quality and durability by allowing liquid metal to cool quickly. Die molds are ideal for mass production and have a long lifespan.

How is a Casting Mold Prepared?

The process of preparing a casting mold varies depending on the casting technique. In sand casting, a sand mixture is placed around a model to form the mold. In die casting, steel or cast iron molds are machined with CNC machines. Mold surfaces are coated to prevent the metal from sticking during casting.

What Are the Advantages of Casting Molds?

Casting molds save time and costs, especially in mass production. Since die molds can be reused, they are more cost-effective in the long term. Additionally, molds provide consistency in parts through high-precision production. Sand casting, on the other hand, is used for producing large and complex parts and offers flexibility.

How Durable Are Casting Molds?

The durability of casting molds depends on the material used and the intensity of the casting process. Die molds made from materials like steel and cast iron can withstand many casting processes. Sand molds are disposable and need to be remade for each casting.

What Products Are Produced with Casting Molds?

Products produced with casting molds include various industrial items such as engine parts, gears, transmission components, hydraulic parts, medical devices, and construction materials. Additionally, artistic and decorative products can also be produced with casting molds.

How Are Casting Molds Cleaned and Maintained?

Casting molds should be regularly cleaned and maintained. In sand molds, compressed air or brushes are typically used to clean the sand and binders. In die molds, care should be taken not to damage the surface while cleaning residues. Furthermore, a coating process can be applied to the mold surfaces to prevent wear during casting.

How Much Do Casting Molds Cost?

The prices of casting molds vary based on the material used, the complexity of the mold, and the number of parts to be produced. Sand casting molds are generally low-cost, but they are disposable. Die molds require a higher initial investment but provide cost advantages in the long run. Precision molds requiring CNC machining are generally more expensive.