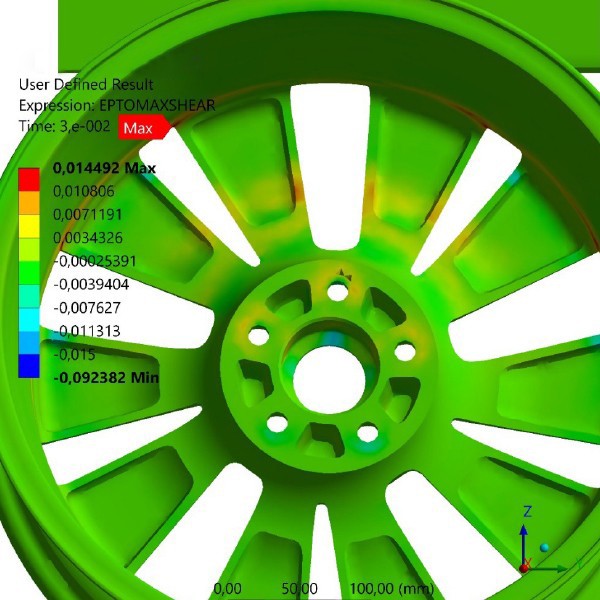

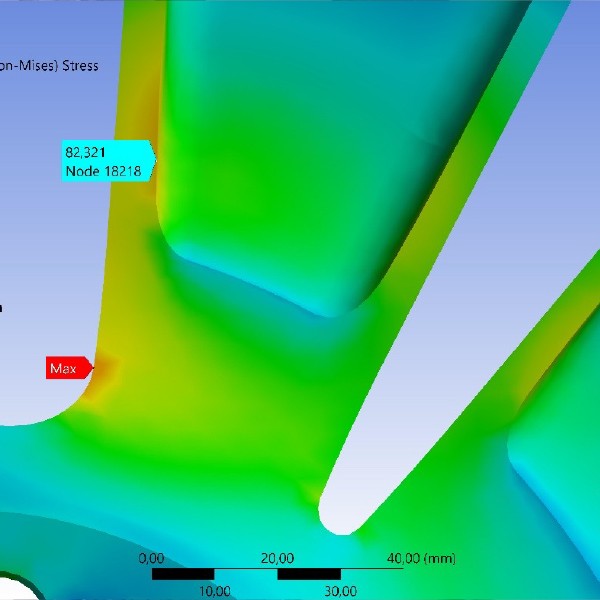

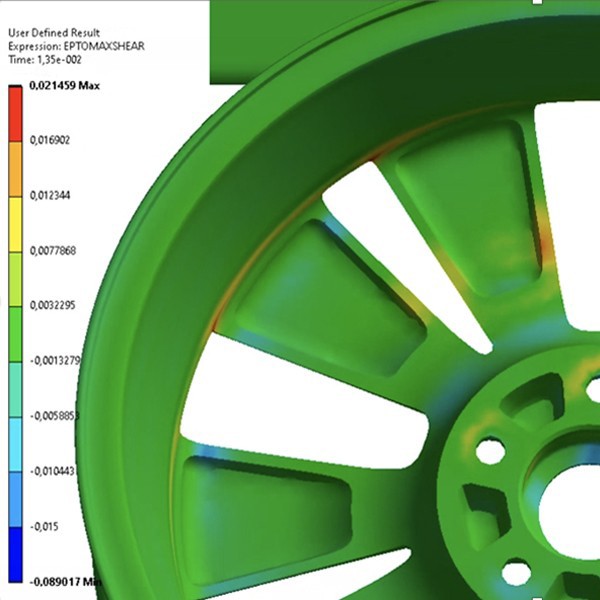

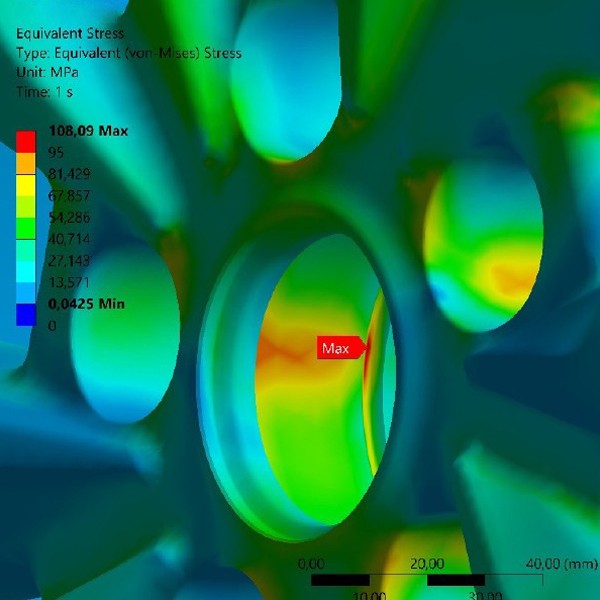

Based on the data obtained from the analysis, areas requiring intervention are identified and reported, and all versions are tested until the perfect result is achieved. All casting simulations necessary for fast prototyping in the manufacturing industry (quick filling, porosity, solidification direction, fluidity, cooling, air gaps, weight, etc.) are carried out using advanced engineering software that shapes the industry.

- +90 236 233 20 03

- info@metamold.com

- Customer Portal